In collaboration with our clients, we have developed a unique tracking system that allows detecting the clogged or damaged sites in the drainage system. This system allows you quickly and accurately locating the drainage pipe damage site, as well as the depth of the flushing pipe. The tracking system will not only significantly increase operational efficiency, it will also save fuel costs while lowering operating costs.

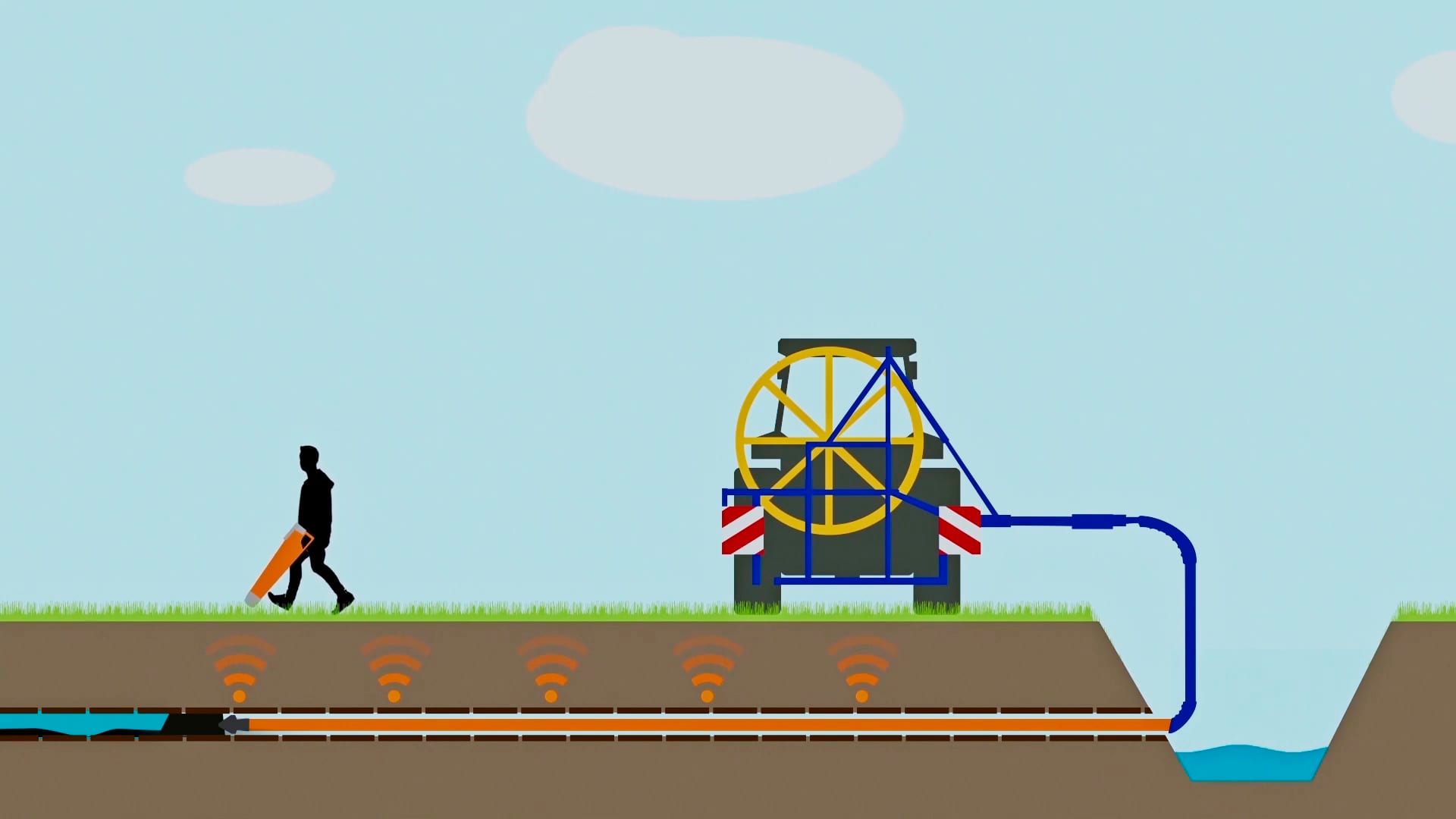

Operating principle. A drainage flushing pipe is inserted into the drainage system drain, which rinses and cleans the drain with water pressure. A flushing pipe is like a sensor, from the beginning to the end of the pipe a signal is sent from the Watt transmitter. Using the vScan signal receiver, it is possible to determine the location of the clogged or damaged site in the drain, where the receiver stops receiving the signal.

Advantages. In drained fields with a functioning drainage system, the plants germinate and grow evenly. Customers who use the drainage flushing tracking system evaluate the efficiency – work efficiency increases by more than 50%, fuel savings of up to 60%. Using the system will reduce operating costs.

Pay attention. The walls of the cleaner pipes are made of durable and high quality materials providing at least 2 times longer service life than the products offered by competitors. Even if the tube is damaged, deformed, or broken, it can be repaired to continue rinsing, keeping the tracking system running.